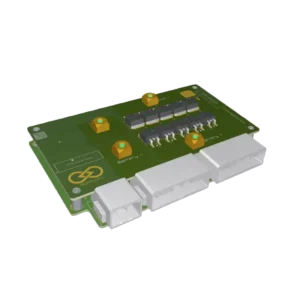

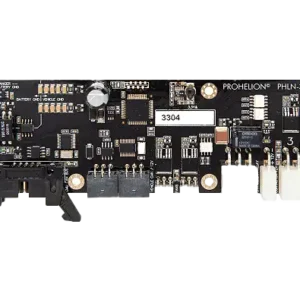

The D1000 Gen2 Cell Management Unit (CMU) represents the next generation of distributed cell monitoring technology in Prohelion’s advanced battery management architecture. As an essential component of the D1000 Gen2 system, each CMU provides precise monitoring of up to 14 individual cell voltages and 4 temperature sensors with exceptional accuracy and enhanced balancing capabilities. Supporting up to 32 CMUs per system, the Gen2 CMU enables comprehensive monitoring of up to 448 cells and 128 temperature sensors across large-scale battery installations. With automotive-grade design, extended temperature operation, and significant improvements over Gen1 technology, the Gen2 CMU is engineered for demanding automotive, industrial, and energy storage applications requiring the highest levels of safety and reliability.

Next Generation Technology: The D1000 Gen2 CMU delivers enhanced capabilities over Gen1, including 14-cell monitoring (vs 8 cells), 650mA balancing current (vs 250mA), 4 temperature sensors, automotive-grade design, and extended temperature operation for mission-critical applications.

The D1000 Gen2 CMU is designed for demanding distributed monitoring applications:

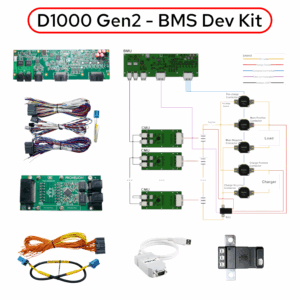

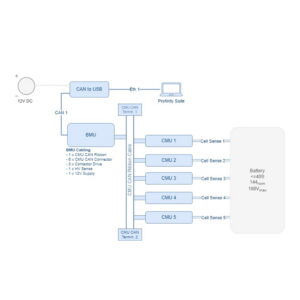

The Gen2 CMU integrates seamlessly within the distributed D1000 Gen2 architecture:

Comprehensive technical documentation and integration guides are available through Prohelion’s documentation portal at: docs.prohelion.com

For technical support, integration assistance, or product inquiries, please visit our support portal where you can find comprehensive resources, submit support tickets, and access our knowledge base for D1000 Gen2 system integration.

$342.26

50 in stock (can be backordered)

© 2025 Prohelion Pty Ltd.